Tesla’s CyberTruck has been grabbing attention in the auto industry since its unveiling in 2019. The cold-rolled stainless steel exoskeleton chassis and innovative manufacturing methods have been generating increasing interest, despite multiple delays in its launch date.

The vehicle’s fan base is constantly on the lookout for latest information, and recent investor day presentations confirmed a long-discussed innovation: its 48-volt electrical architecture.

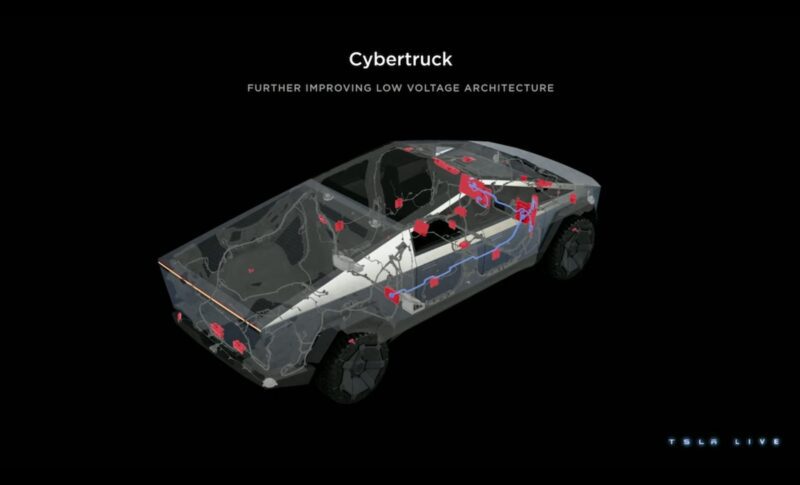

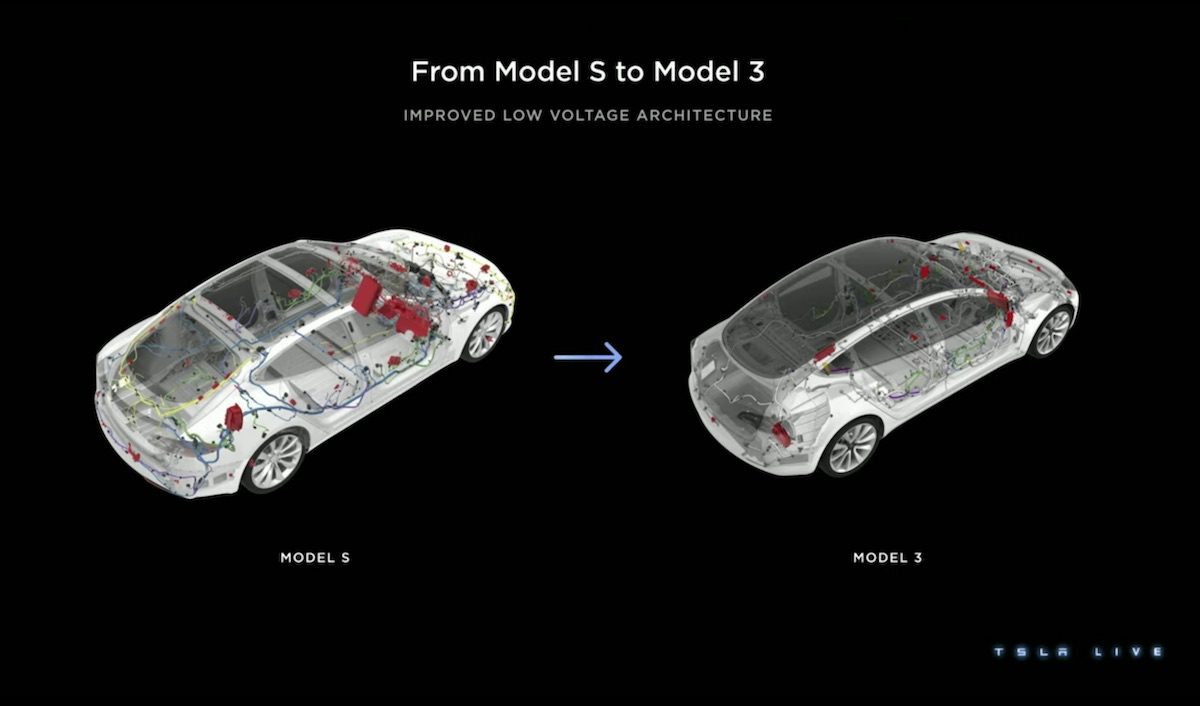

While 48v systems have been partially utilised in mild hybrid vehicles for a few years now in high draw componentry, the CyberTruck replacement of the traditional 12v system is a significant step forward for the auto industry. In traditional 12v systems, wiring and components must be larger and heavier to handle high electrical loads.

However, a 48v system can accommodate high loads more efficiently, which reduces the size and weight of wiring especially for low draw componentry. This translates to better vehicle efficiency, better handling and production efficiency.

Legacy automakers have been slow to fully adopt 48-volt technology due to their dependence on third party suppliers, who may not be equipped to manage a rapid transition to a new system voltage. In a recent Autoline Daily interview, Sandy Monroe noted that “Everybody has been talking about doing this for 30 years, but they did it.”

According to Cory Steuben, President of Monroe and Associates, manufacturers and suppliers will have to switch to 48 volts: “Either the customer will pay, or the car maker will take the profit loss of not adopting 48 volts.”

As more automakers recognise the benefits of the 48-volt system, they will be compelled to invest in the necessary technology and infrastructure to make the switch. Failure to do so could result in a loss of market share and profitability.

Tesla’s vertical integration, manufacturing capabilities, and corporate structure give them an unprecedented agility to design and produce their own highly integrated components in-house, enabling a swift transition to the 48-volt system.

The implementation of this technology in the CyberTruck provides several advantages. The 48-volt system enables more efficient power delivery and handling of higher electrical loads with smaller cabling, resulting in lower overall weight and greater efficiency gains.

“Secret” accessories team developing lighting, winches and air compressors

Moreover, Tesla’s decision to use a 48-volt system gives them a significant edge when it comes to accessories and add-ons for the CyberTruck.

As reported by Matthew Donegan-Ryan, a TSLA retail investor who spoke with Tesla executives at a recent investor day at the company’s Austin headquarters, Tesla has its own “secret” accessories team dedicated to developing products specifically for the 48-volt architecture, such as lighting, winches, and air compressors.

These products are designed to work seamlessly with the CyberTruck systems, offering customers a wide range of high-quality accessories that are tailored to the vehicle’s capabilities. With this approach, Tesla not only aims to provide a superior product to its customers but also creates new revenue streams and strengthens its brand image as a leader in innovation and design.

The members of the CyberTruck fan site Cybertruckownersclub.com have been letting their imagination run wild over this development hoping that the ‘Secret accessories team’ would consider some of their

ideas.

48-volt system brings new opportunities but also risks to be addressed

While the 48-volt system offers advantages in terms of efficiency and weight reduction, it also presents new challenges in terms of complexity and safety.

These challenges could include issues such as the need for new safety features to protect against electrical shock. These challenges are likely to be behind legacy manufacturers apprehension and reticence to fully adopt 48v for parts of the vehicle a consumer would directly interact with.

Tesla’s adoption of a 48-volt electrical architecture in the CyberTruck represents a significant step forward for the auto industry and aligns with the company’s mission to accelerate the world’s transition to sustainable energy and transport.

By designing and manufacturing their own components in-house, Tesla will be able to seamlessly transition to this innovative technology, giving them a distinct advantage in the market.

The 48-volt electrical architecture presents new challenges to reduce complexity and increase safety, but Tesla’s adoption of this technology in the CyberTruck marks a significant step forward for the auto industry.

With their vertical integration, manufacturing capabilities, and corporate structure, Tesla is uniquely positioned to design and produce highly integrated components in-house, enabling a swift transition to the 48-volt system.

By taking advantage of the benefits offered by the 48-volt system, such as improved power delivery, handling of higher electrical loads, lower weight, and greater efficiency gains, Tesla is establishing a distinct advantage in the market.

The company’s “secret” accessories team is dedicated to developing products that work seamlessly with the CyberTruck systems, which not only provides a superior product to customers but also creates new revenue streams and strengthens Tesla’s brand image as a leader in innovation and design.

As legacy automakers struggle to adapt to new technologies, Tesla’s gains with the 48-volt system will serve as a reminder of the importance of vertical integration, innovation in manufacturing capabilities, and corporate structure in the seamless transition to sustainable transportation.

With its continued investment in research and development, Tesla is poised to continue leading the way in the electric vehicle industry, playing a key role in the world’s transition to a sustainable energy future.