Tesla’s Berlin factory has reached a run rate of 4,000 electric cars per week. The production milestone comes after the new factory hit 3,000 cars per week in December, and reflects a 33% increase in production in just two months.

Giga Berlin opened on March 22, 2022, around a month before Tesla’s other massive factory, Giga Texas opened in Austin.

4k Model Y built at Giga Berlin this week 🤘

Congrats to the Tesla team! pic.twitter.com/VJ0qBPkQ6U

— Tesla Europe (@tesla_europe) February 27, 2023

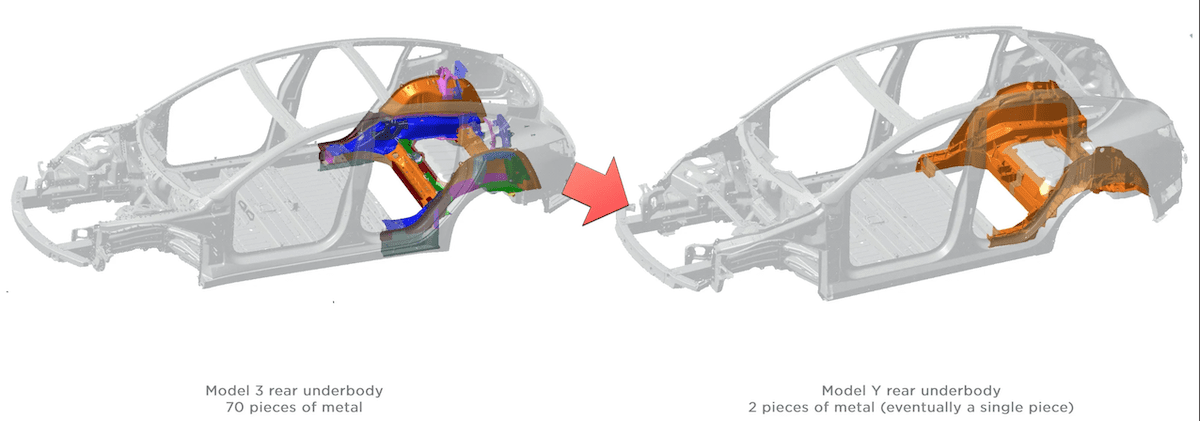

Giga Berlin and Giga Texas are considered two of the most advanced automotive factories on earth. Both factories are already using revolutionary manufacturing techniques not seen anywhere else in the world. One of these new techniques is Tesla’s “unibody” or single-body castings which are being used to make the Model Y at Giga Berlin.

The giant single-body castings are built with the largest high-pressure die casting machines in the world and enable Tesla to make whole sections of the car that traditionally required the welding of hundreds of seperate parts.

The castings are so large that Tesla’s materials engineers had to develop a new aluminium alloy to enable the molten aluminium to flow into all the intricate areas of the die before setting. A truely revolutionary breakthrough in engineering.

You can see the Giga Press in action in Tesla’s Giga Berlin Fly through video. At 1:05 you’ll see a robot removing the Model Y single piece rear underbody casting from the Giga Press.

At Giga Berlin, each car takes 10 hours to produce. This is three times the speed of Volkswagen’s Zwickau plant which takes 30 hours to produce a car.

At 4000 cars per week, Giga Berlin currently has an annualised production rate of just over 200,000 cars per year. The first stage of production will scale to an annualised rate of 500,000 cars per year but the factory has the capacity to eventually produce up to 2 million per year.

Although originally slated to also produce Tesla’s new 4680 structural battery packs, Tesla recently announced that the Berlin battery production would now be moved to the US to take advantage of the huge $US35 per kWh Advanced Manufacturing Credits, part of the Biden Administrations Inflation Reduction Act.

The battery tax credits, which work out to be worth over $US2000 for every vehicle made with a 60kWh battery pack, have sparked an EV arms race which is supercharging battery manufacturing in the US. Companies from around the world are now scrambling to build factories in the US to take advantage of the credits.

Giga Berlin’s production milestone comes just days before Tesla’s Investor Day event which will showcase some of the game-changing manufacturing advances made at Giga Berlin.

CEO Elon Musk has also said Tesla’s “Master Plan 3” will be announced during the Investor Day event and has given hints that details on Tesla’s a 3rd generation platform will also be announced. There is strong speculation that this 3rd generation platform will significantly reduce Tesla’s production costs and pave the way to a $US25,000 model.

An high quality electric vehicle that is not only cheaper to run and maintain, but also cheaper to buy will be the final nail in the coffin for internal combustion engine vehicles.

Tesla’s Investor Day on March 1 could end up being the most significant moment in automotive history since Henry Ford’s Model T started rolling off mass production lines over 100 years ago.

Daniel Bleakley is a clean technology researcher and advocate with a background in engineering and business. He has a strong interest in electric vehicles, renewable energy, manufacturing and public policy.