Recharge Industries has engaged global consultancy firm Accenture as its engineering provider to build what is likely to be Australia’s first large-scale lithium-ion battery cell production facility focusing on the electric vehicle market.

The facility, to be located in Geelong, Victoria, in the heartland of what was once a thriving auto manufacturing industry, is set to begin construction in the second half of 2023.

The company estimates that the factory will have a 2 gigawatt hour (GWh) annualised production rate by the end of 2024, rising to 6GWh in 2026 then scaling to an annual production capacity of 30GWh.

The company says it has already secured the equipment for the first 2GWh production line and that it will produce batteries for both electric vehicle and the stationary storage market.

Queensland report points to massive battery demand

The announcement came on the same day as the Queensland Government released a discussion paper (also produced by Accenture) titled Battery industry opportunities for Queensland which estimates that annual global demand for batteries will reach a massive 2,045GWh in 2030.

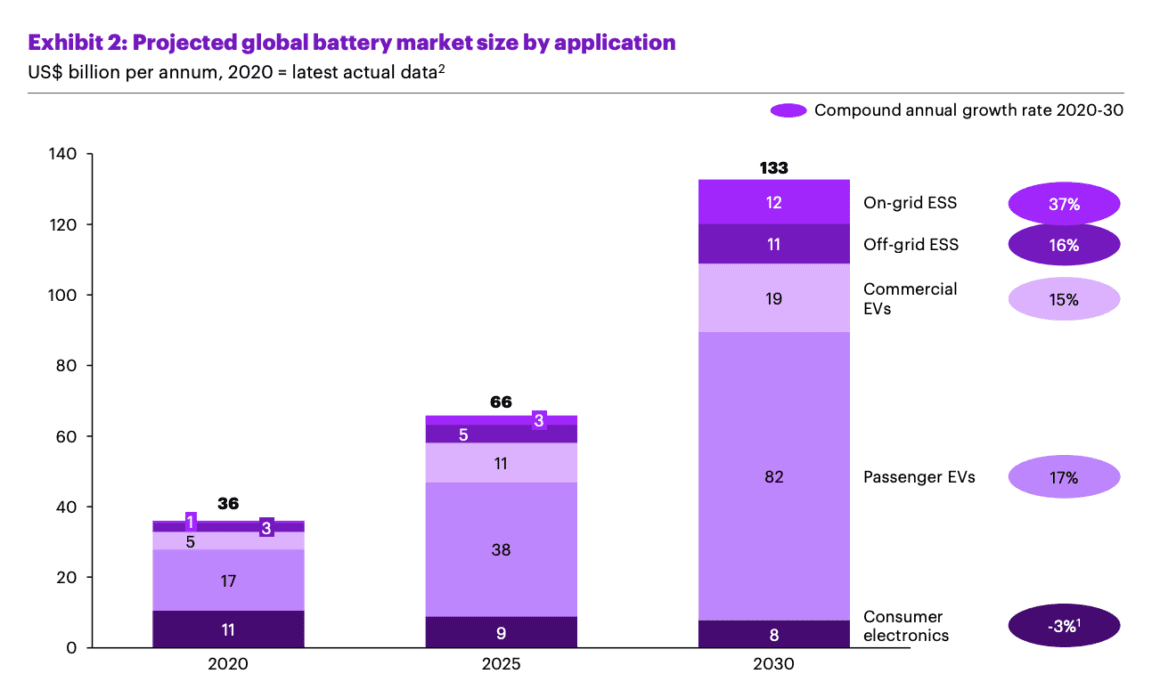

The paper estimates that in 7 years the total market will be worth $A190 billion comprising $A144 billion for commercial and passenger electric vehicles, $16 billion for off-grid stationary storage and $17 billion for grid-connected storage systems. The growth in the grid-connected battery market is estimated to be 37% per annum to 2030.

The discussion paper shows that Australia already supplies 50% of the world’s battery minerals by value. Positioning refining, processing, and even manufacturing closer to the source of raw minerals reduces excess freight costs that are associated with transporting heavier unprocessed resources.

Opportunities limited by lack of local car making

Despite this the paper says that in the medium term there are limited opportunities to supply the electric vehicle market because of existing strong competition from local battery producers in EV manufacturing countries.

The paper suggests that for Queensland the main opportunities are in the stationary storage market. While the Geelong plant is planning on producing batteries for both EVs and stationary storage, it will be interesting to see the proportion breakdown.

If Recharge Industries can execute its plan it has the potential to reinvigorate Australia’s manufacturing industry after the automotive sector was completely wiped out when Holden, Ford, Toyota and Mitsubishi all closed their Australian factories over the last two decades.

“Establishing a sovereign manufacturing capability to produce state-of-the-art lithium-ion battery cells is critical to Australia’s renewable energy economy meeting national demand, generating export income and securing supply chains,” Rob Fitzpatrick, CEO of Recharge Industries, said in a statement.

“Our factory, which we are building with the assistance of Accenture’s engineering and capital projects expertise and underpinned by C4V’s IP and battery technology, will create thousands of jobs and attract large-scale investment from key players in Australia, the Indo-Pacific region, and other parts of the world.”

Daniel Bleakley is a clean technology researcher and advocate with a background in engineering and business. He has a strong interest in electric vehicles, renewable energy, manufacturing and public policy.