The purpose of switching from fossil fuels (petrol/diesel/LPG) to low-emission alternative fuels is to reduce/mitigate climate change by reducing the country’s total CO2 emissions.

If an alternative fuel/powertrain can be deployed which has a lower cost per km than fossil fuels, is fit-for-purpose, and has no significant disadvantages (e.g. power, torque, safety), then the market will probably naturally and speedily gravitate to the new fuel/drivetrain.

Thus, any viable market-changing solution must reduce costs, not just emissions.

Earlier this week, we published the first part of our two-part series on Hydrogen for land transport. That article focused on emissions and distribution. This second part will focus on costs.

In the previous article, we examined the options for producing Hydrogen. While Electrolysis could use renewable energy to produce Hydrogen with no production CO2 emissions, the high cost, the large amount of energy required and the significant amount of water needed make this process unviable in practice.

Steam Methane Reforming can produce Hydrogen using less energy and at lower cost than electrolysis but produces higher emissions than petrol and costs more than petrol.

We also examined the costs and emissions relating to distribution of Hydrogen from central refineries to local service stations, considering compression, liquefaction and ammonia options.

It was found that energy/water required and emissions produced from using Hydrogen, as opposed to petrol, made the switch unsuited to achieve the goals of the exercise.

In other words, using Hydrogen produces significant emissions when compared with petrol and also uses significant quantities of water. Hydrogen would also require massive expansion of national power generation and transmission infrastructure.

This article examines costs of infrastructure required to facilitate a switch to a Hydrogen transport solution, and the costs of the fuel itself.

Hydrogen Infrastructure

Despite in-principle support for the concept of Hydrogen infrastructure from one or two Japanese and Korean car manufacturers and support from the oil industry and power industry, none of these parties seem willing to invest in Hydrogen infrastructure.

(It should be noted that Toyota has invested heavily in Hydrogen research over the years and owns over 6,000 patents relating to Hydrogen fuel cells).

Instead, calls are persistently made by these stakeholders to governments around the world to pay for the Hydrogen infrastructure.

So how much Is Hydrogen infrastructure likely to cost? Is there a business case for a Hydrogen pump?

- Costs of the industrial-scale refineries required will be – industrial. Switching the Australian fleet to Hydrogen would require over 10 Mt of Hydrogen a year. Cost/supply of water could also be a real, emotional and political issue in drought-affected areas.

- Costs of operating suitable specialised trucks to transport the Hydrogen on roads safely – and without Hydrogen leaking on the way – will be significant.

- Costs of Hydrogen pumps are high. Current installation costs in US are around USD$1.5m per pump. Since Australia currently has 6,400 service stations and, assuming (for example) that an average of 6 Hydrogen pumps per service station will be required to replace the existing petrol pumps, the total cost could run into around AUD$86 billion, although some commercialisation savings would apply to a large-scale deployment.

From these figures, it is clear why industry doesn’t want to pay for it. To recover the cost of a AUD2.2m pump alone (ignoring costs of capital, refineries, logistics, feedstock, insurance and wages), and assuming that a pump refuels 50 cars a day, and assuming that the cost recovery takes place over 5 years, it would have to make a profit of AUD$5 per kg, just for the pump.

The total costs of production inputs (energy, water, methane), production and retail infrastructure, frequent delivery of Hydrogen (up to several times a day for a busy pump) and wages contributes to significant extra costs for Hydrogen which, presumably, the motorist will have to pay. Or the taxpayer if the government provides a subsidy.

The retail price of Hydrogen is currently USD$16 (AUD$24) per kg Hydrogen in Los Angeles, making it (currently) nearly double the current price for Australian petrol.

From a financial perspective, it is hard to see how the much less expensive SMR production method (see article 1) can be avoided, and so using Hydrogen fails the two requirements of switching from petrol to Hydrogen, i.e. lower emissions and lower cost. Hydrogen produced from SMR results in similar emissions to a petrol car but costs about twice as much.

The question has to be asked: why switch from petrol to Hydrogen?

Japan has its own political reasons for switching to a purely Hydrogen economy which are unique to Japan. They simply don’t apply anywhere else.

Maybe Hydrogen cars provide other benefits…

Let’s examine features of the Hydrogen fuel cell vehicles themselves to identify any advantages that they offer over petrol.

Number of vehicles sold

Apparently almost 9,000 Hydrogen vehicles are on the road in US and Japan (with a few more in the rest of the world). The only commercially available cars are (mainly) the Toyota Mirai, with the other two from Honda and Hyundai.

Vehicle cost:

Costs of currently available Hydrogen Fuel Cell vehicles : (based on US prices, as Australian prices do not appear to be available)

Toyota Mirai: US: USD60,000; Aus: nothing on website; assume AUD90,000 or more

Hyundai Nexo: US: USD60,000; Aus: nothing on website; assume AUD90,000 or more

Honda Clarity FCV: US: 3-year lease only (USD2800 deposit + USD390 per month); Aus: no plans

Acceleration (0-100km/h)

Hyundai iX35: 12.5s (discontinued)

Hyundai Nexo: 9.5s

Toyota Mirai: 9s

Honda Clarity: 9s

These vehicles accelerate slightly faster than a Prius (10s).

Vehicle re-fuel time (and behaviour)

The big selling point of Hydrogen fuel cell vehicles is that you can (supposedly) re-fuel in 5 minutes and your behaviour does not need to change – you can still go to the service station to refuel.

Hydrogen: Hydrogen pump equipment is usually coupled with a storage capacity of 180kg of Hydrogen at 700 bar of pressure, per pump. A 180kg storage tank can completely refill up to 36 cars before it is empty.

When the tank is used back-to-back to refill cars, assuming 5 minutes per car, there canbe temporary lag periods after a few cars have refilled, where the reduced pressure in the storage tank needs to be restored, using pumps, to maintain a suitable pump-pressure/flow-rate.

If a pump were used continuously for refilling cars with a 15-minute lag time after every third car (i.e. filling 6 cars per hour), then the pump’s storage tank would be emptied after 6 hours.

In summary, you can refill in as little as 5 minutes, but it could take 20 minutes if you are unlucky. (You are also a price-taker at the pump).

Lithium battery vehicles: The fundamental difference between Lithium battery vehicles and other vehicles (petrol/diesel/LPG/Hydrogen) is that they do not need to go to a service station.

They do not normally need to be filled up because they can be topped up when they are parked; viz. at home and/or at work and/or at destinations such as shopping centres.

Lithium battery vehicle owners almost never use public infrastructure to fill-up because they tend to re-charge their battery to – literally – full, most days.

However, if they do need to use public fast-charge infrastructure (e.g. if they don’t have home/work charging available), they can, it’s fast and it’s getting faster – up to 2,000km an hour.

That’s up to a 15 minute wait to re-fill to 500km from empty, but probably only a few times a year. (Note: vehicles capable of handling that speed of re-charge are only starting to come out now; right now the vehicles are catching up with the charging infrastructure).

Alternatively, people who can’t re-charge at home or work may choose to buy PHEVs rather than BEVs. (And electricity is a fraction of the cost of petrol/Hydrogen, per km).

In other words, the refuelling time of Hydrogen (which may sometimes take longer than 15 minutes as explained above) is no longer an advantage of Hydrogen.

This loss of Hydrogen’s claimed advantage is partly due to hydrogen pumps being a little unpredictable but mainly because EVs – which are topped up while the car is parked – almost never need to interrupt a trip to re-charge at public infrastructure.

Range: Lithium battery vehicles also have similar range to Hydrogen vehicles these days. The lowest (real-world) ranges are 300 km (e.g. BMW i3, Renault Zoe) and the higher real-world ranges are between 400 km and 500 km (e.g. Hyundai Kona, Hyundai Ioniq, Kia Niro, Teslas, etc etc).

And of course, PHEVs don’t have a range problem because of their duplicate petrol powertrain, addressing such situations.

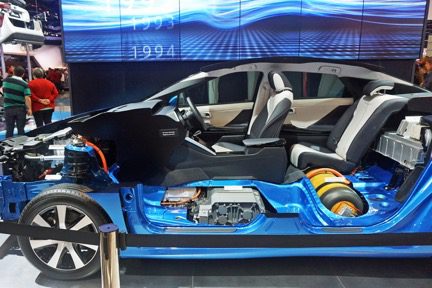

Volume and weight of a Hydrogen tank, fuel cell stack and battery

The problem with storing Hydrogen in a vehicle is that is takes up quite a bit of space. For example, 5kg of Hydrogen, compressed to 700 bar, requires a tank of around 125 Litres.

This is much bigger than a petrol tank with a similar range and it could be an issue in smaller hatchbacks which don’t have much space in the boot or under the seats.

It would be interesting to know whether a hatchback can use Hydrogen and how much boot space would be left.

A Mirai’s 5kg Hydrogen tank is reported to be 85kg which is surprisingly heavy and is located under the back seat.

Toyota persists in using a NiMH battery which is tried-and-tested Prius technology from the 1990s, but, as can be seen in the cutaway photo, is enormous in size for the amount of energy; it appears in the picture behind the back seats and contains only 1 kWh. The fuel cell stack is under the front seats, and the electric motor is the front cavity.

All of this equipment needs costly maintenance to prevent leaks, etc, but preserves the business model of the motor-dealer, albeit at the expense of the driver.

In summary, it’s hard to see why it is worth considering Hydrogen for light road transport. The cars are more expensive, not fast, need maintenance, and there are only three to choose from, with no others on the horizon.

The fuel is more expensive; there are no Hydrogen pumps or other infrastructure; Hydrogen produces more emissions than petrol and it needs water.

The original goals of this series of articles were to examine whether Hydrogen will reduce either cost or emissions, compared to petrol.

It doesn’t.

Bede Doherty is an independent consultant in climate change mitigation, specialising in transport including fuels/powertrains, fuelling infrastructure and emissions.