Lithium is currently leading the race when it comes to electric vehicles’ battery choice. However, a “proton” battery from a RMIT research team could one day provide EV users with similar energy storage to lithium, without the environmental costs.

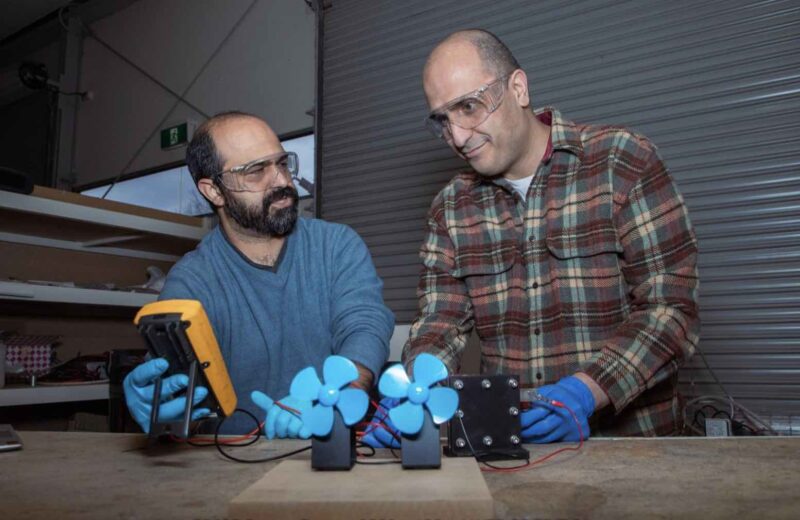

The proton battery or a ‘proton-exchange membrane’ recently hit an exciting milestone – a hydrogen weight percentage capacity of 2.23. That’s three times what they’ve previously been able to achieve and on par with lithium batteries. Research into the battery has been published in the Journal of Power Sources.

“Our battery has an energy-per-unit mass already comparable with commercially-available lithium-ion batteries, while being much safer and better for the planet in terms of taking less resources out of the ground,” said one of the researchers, RMIT Professor John Andrews.

“Our battery is also potentially capable of very fast charging.”

Batteries like lead-acid, vanadium or most sodium batteries aren’t as appropriate for electric vehicles as lithium ion is because their ‘energy density’ is lower.

The lower the energy density, the more battery (and weight) you need to add to car for it to go the equivalent distance. Lithium-ion is currently one of the highest energy density rechargeable batteries on the market.

This new proton battery from the team at RMIT has an energy density much closer to a lithium-ion battery, although there is still a long way to go before we’ll be seeing it in our EVs.

“As the world shifts to intermittent renewable energy to achieve net-zero greenhouse emissions, additional storage options that are efficient, cheap, safe and have secure supply chains will be in high demand,” said Andrews.

“That’s where this proton battery – which is a very equitable and safe technology – could have real value and why we are keen to continue developing it into a viable commercial alternative.”

The battery works more like a fuel cell then a traditional battery. In the ‘electrolyser mode’ when the system is charging, the battery splits water molecules to create protons, which then move across a membrane to bond to a carbon electrode. Then when discharging in the ‘fuel cell mode’, the protons are transferred back to the other side of the system to turn back into water.

“Our proton battery has much lower losses than conventional hydrogen systems, making it directly comparable to lithium-ion batteries in terms of energy efficiency,” says Andrews.

“The main resource used in our proton battery is carbon, which is abundant, available in all countries and cheap compared to the resources needed for other types of rechargeable battery such as lithium, cobalt and vanadium.”

If these batteries are successful in EVs, it may take some pressure off the huge amount of lithium we’re going to need for the energy transition. There’s also the difficulties of recycling lithium at the end of it’s life.

The team also discovered the system had an added benefit – hydrogen. The proton carbon electrode was able to produce high purity hydrogen gas, meaning the system could instead be used to store hydrogen without some of the problems of transporting the slippery gas.

You won’t be seeing proton batteries in your car any time soon though. Currently the system is only in the ‘watt’ level and much more research will need to be done before kilowatt or megawatt proton batteries are available.

“We are looking forward to developing this technology further in Melbourne and Italy, in partnership with Eldor Corporation, to produce a prototype battery with a storage capacity that meets the needs of a range of domestic and commercial applications,” Andrews said.