Israeli company StoreDot has filed a patent for its extremely fast-charging battery technology, taking it one step closer to commercial availability for electric vehicle makers.

Dubbed “XFC” by the company, StoreDot hopes that its new approach to battery chemistry will be a step-change for automotive industry, and says it will make it open source for those interested (although likely not free).

Numerous studies show that many drivers are holding off switching to clean, electric transport because there are times they would need the recharging experience to match that of refuelling an internal combustion engine vehicle.

“This is an important step for the EV global community as it will allow all of us to charge faster with very minimal changes to the current infrastructure and future deployment process. That is why we believe it’s critical to offer this world-leading innovation to other organizations on an open-source basis,” said StoreDot CEO Dr Doron Myersdorf in a statement.

StoreDot says its chemistry, which is a stepping stone between traditional lithium-ion chemistries and solid-state chemistry (considered the holy grail of battery charging), can reduce current charging times by 50%.

In early 2021, it demonstrated this by charging a commercial drone in five minutes.

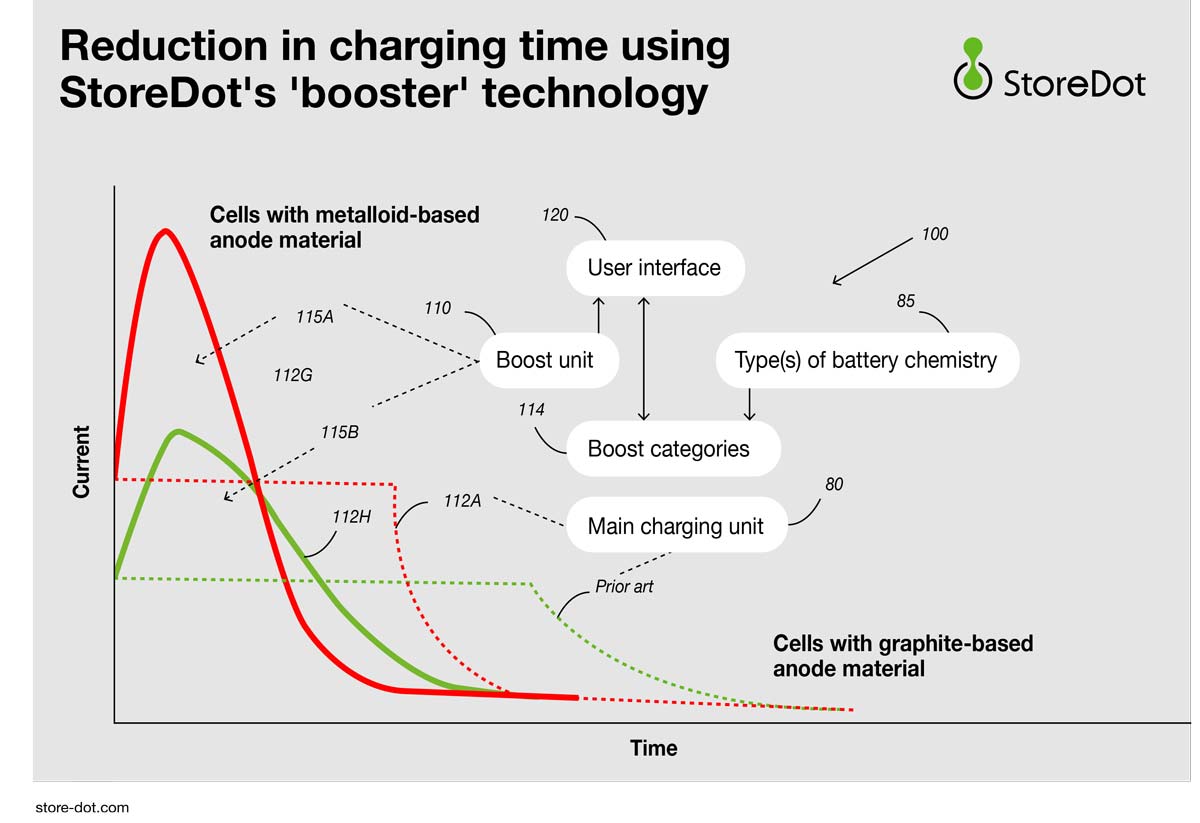

A new graph shared by the company illustrates how its technology reduces the charging time of lithium-ion batteries, by using a silicon metalloid-based anode material instead of a graphite-based material that allows an initial higher current that it bills as a “booster” feature.

“This communication between a vehicle’s XFC battery and charging system means that cells can be charged faster, safely accepting a higher current without overheating,” said the company in a release about the patent.

“It also has the ability to immediately boost existing infrastructure systems, enabling faster charging, and thus optimising future fast-charge technologies without the need to upgrade to newer equipment in the near future.”

And it won’t cost the metaphorical earth, according to an informative video on the company’s website. Myersdorf says that making its XFC batteries could in fact be cheaper than traditional lithium-ion batteries because in some cases silicon can be cheaper than graphite.

However, scale is needed to process the silicon nanoparticles needed to create their XFC anode chemistry.

Its plans for XFC batteries also faces challenges in building a silicon supply chain, again an issue of scale. To counter this, it says it is developing partnerships with supply chain partners – although how this will play out with a global silicon semiconductor shortage causing havoc in many industries only time will tell.

“The global uptake and appeal of electric vehicles is crucial if we want to live in a cleaner, zero-emissions world and by sharing this novel approach StoreDot aims to play a pivotal role in helping to achieve this objective,” says Myersdorf.

We want to work with and support the global community, including automotive manufacturers and infrastructure providers in their missions as well, especially when the industry is facing a number of charging infrastructure deployment challenges, not least the global semiconductor shortage.”

Bridie Schmidt is associate editor for The Driven, sister site of Renew Economy. She has been writing about electric vehicles since 2018, and has a keen interest in the role that zero-emissions transport has to play in sustainability. She has participated in podcasts such as Download This Show with Marc Fennell and Shirtloads of Science with Karl Kruszelnicki and is co-organiser of the Northern Rivers Electric Vehicle Forum. Bridie also owns a Tesla Model Y and has it available for hire on evee.com.au.