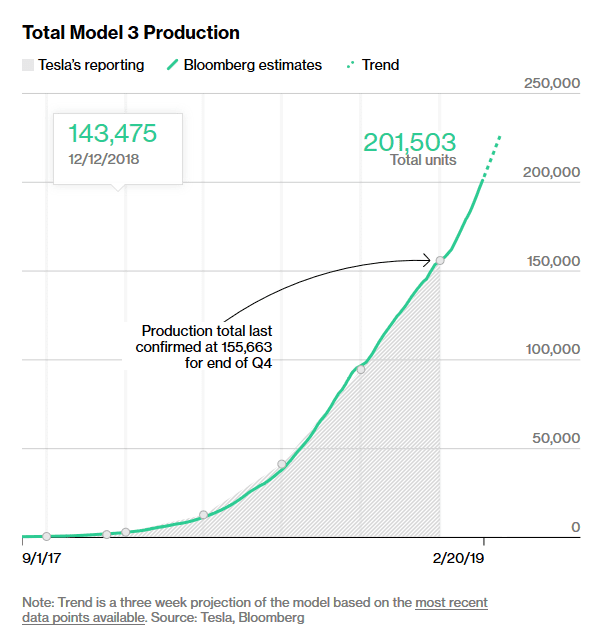

There are now over 200,000 of Tesla’s all-electric Model 3 vehicles on the planet, according to estimates recorded on Bloomberg’s Tesla Model 3 Tracker.

That’s around the same amount EVs in total on the road in leading EV market (in terms of share), Norway.

Given the fact that Model 3 deliveries began in mid-July 2017, that is around 19 months ago, this works out to an average of around 10,000 Model 3s per month.

The majority of these vehicles are of course driving around in the US, although the global diaspora that are Model 3 exports are now on the road to multiplying rapidly, with ships transporting Model 3s arriving in recent weeks in both Europe and China.

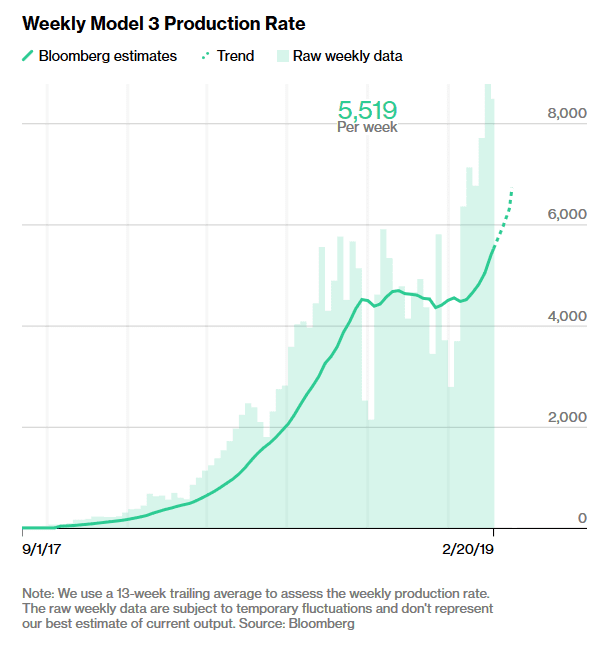

It must be noted that production has not been at a steady rate for that entire time.

In the first quarter that Model 3 deliveries were reported (Q3, 2017), 222 Model 3s were delivered, all to employees, followed by 1,542 Model 3s when deliveries to non-employees commenced.

This has been steadily ramped up, as reported by both Tesla itself and Bloomberg’s Tesla Model 3 Trackers webpage which is based on a combination of registered VINS and self-reported VINs either through Bloomberg’s own submission form or via the Tesla Model 3 Owner’s Club order tracker spreadsheet, among others.

Going off the last reported accumulative total (155,663 units), there have been around 45,000 Model 3s produced since the last quarterly reporting date (Q4 2018).

This equates to an average of around 6,500 Model 3s now being produced a week for the last 7 weeks, although according to Bloomberg’s 13 week trailing method the latest weekly output is 5,519 units for the last seven days.

It seems that CEO and founder Elon Musk’s goal to reach 7,000 per week is now achievable -the goal that the electric car entreprenuer has said will be required to be able to move into production of a $US35,000 “standard” version of the Model 3.

Despite so much negativity that the EV maker as a startup would fail, the Model 3 is proving Tesla’s success.

While registered VINs do not necessarily a completed car make, Bloomberg notes their method aligns the two data sets (registered and self-reported) to create an estimate – which has largely aligned with Tesla’s own reports.

Deliveries have now commenced in Europe, with German EV rental company nextmove receiving its first 4 Model 3s on Monday (Europe time), and deliveries in China are imminent, so Tesla is now not so much burdened but gladly tasking itself with continuing the production ramp at its Fremont factory.

It will then complement production at its US facility with the opening of its Shanghai Gigafactory which is now being contructed and is set to open later this year.

At the Q4 2018 earnings call, CEO and founder Elon Musk said, “Earlier this month we started construction of Gigafactory Shanghai, and by the end of this year we expect to be producing Model 3s using a complete vehicle production – that’s body paint, body assembly, general assembly and module production.”

Production is currently entirely left-hand drive for the European and Chinese markets, however with the UK Model 3 configurator now online, right-hand drive production can not be far off and with that, the much anticipated Australian configurator.

Bridie Schmidt is associate editor for The Driven, sister site of Renew Economy. She has been writing about electric vehicles since 2018, and has a keen interest in the role that zero-emissions transport has to play in sustainability. She has participated in podcasts such as Download This Show with Marc Fennell and Shirtloads of Science with Karl Kruszelnicki and is co-organiser of the Northern Rivers Electric Vehicle Forum. Bridie also owns a Tesla Model Y and has it available for hire on evee.com.au.