ANU has teamed up with SunDrive, the developer of unique copper-based solar technology, for its latest solar powered car ahead of the 17th edition of the iconic 3,000km World Solar Challenge race from Darwin to Adelaide.

The event was first launched in 1987 and is held every two years, attracting universities and technical institutes from around the world to showcase their latest innovative solar-powered vehicles.

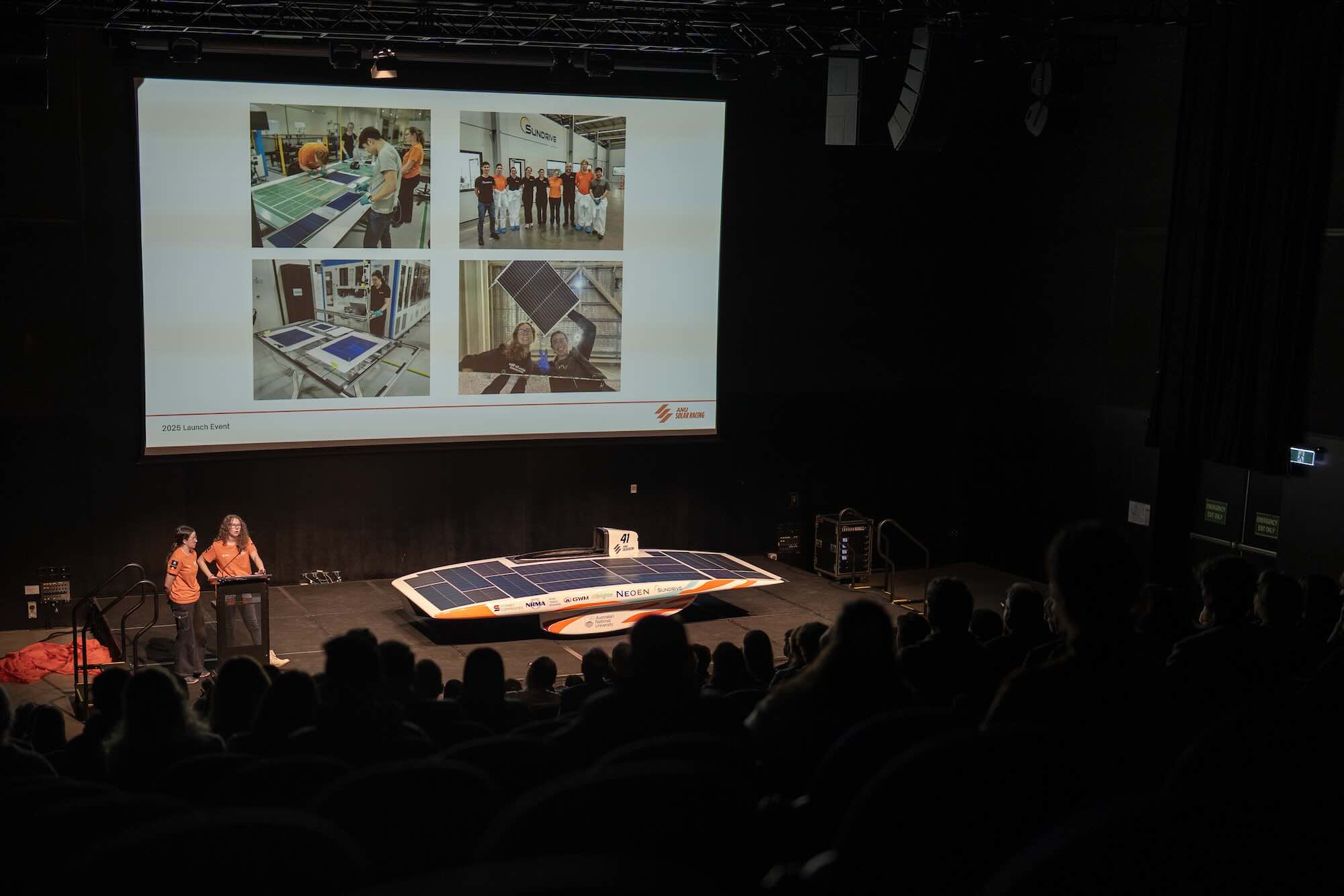

ANU’s fourth and newest vehicle iteration is a solar array manufactured with SunDrive Solar, using heterojunction (HJT) photovoltaic solar cells fabricated at SunDrive’s Australian manufacturing facility.

Last month, SunDrive announced it had entered into a partnership with two Chinese solar manufacturing firms to get its homegrown copper-based solar technology up and running.

Unlike the majority of other manufacturers, SolarDrive is pioneering the use of copper, instead of silver, during the metallisation of its solar cells.

With copper being significantly cheaper than silver, SolarDrive is aiming to reduce the cost of solar installation by 20-30% compared to other high-efficiency options.

“Partnerships like SunDrive exemplify the spirit and ingenuity that the World Solar Challenge attracts. Some of the most advanced technology is tried and tested in some of the harshest conditions,” said ANU’s Solar Racing Business Lead, Cameron Wallace.

Solar racing challenge

With companies such as Bridgestone and Tesla sponsoring the event, the World Solar Challenge enables the next generation of engineers to be involved with something as close to real industry as possible whilst still being a student.

SunDrive provided ANU students with an opportunity to visit its manufacturing facility and allowed them to work on their own solar array by hand.

“It was a valuable experience in applying cutting-edge solar technology and showcasing Australian manufacturing capability on a global stage,” the ANU team said.

After this experience, students utilised skills they’d learnt to lay-up their carbon fibre chassis over an “intensive” four week manufacturing period. For this year’s race, the team will also be debuting its in-house battery management system which it hopes will provide enhanced electrical efficiency and improve safety management features.

ANU will face steep competition come August, including the Belgium based Innoptus Solar Team who won the most recent event in 2023 with an average speed of 88.65km/h.