The Australian federal government is seeking public feedback on its plans to introduce a noxious emissions standard for non-road diesel engines, which will include farm and mining equipment such as tractors, cranes, loaders, excavators, bulldozers, forklifts, pumps, and generators.

The public consultation period on the draft proposals, which was launched over a month ago, has gained little attention with no official government announcement or media coverage.

Non-road diesel equipment actually burns a comparable amount of diesel to the 5 million diesel vehicles that are allowed on Australian roads, and is therefore a huge source of unregulated noxious emissions.

Indeed, according to the government’s own consultation page, non-road diesel equipment is “the largest unregulated” source of pollution in Australia.

“These emissions are harmful to human health and the environment. They are carcinogenic, and contribute to premature deaths, cardiovascular and respiratory diseases,” the paper says.

“Noxious air pollution emitted by these engines poses a significant health risk. Standards were implemented in the United States and European Union over twenty years ago and low-emitting technology is already available.

“Introducing a national emission standard will accelerate the uptake of cleaner technologies and help Australians to live longer, healthier lives.”

The government says future management of diesel equipment will mean changes for industry and individuals. The Department of Climate Change, Energy, the Environment and Water is preparing an impact analysis to advise government on the likely impacts to stakeholders and is taking public submissions on draft analysis until July 14.

Feedback on the draft impact analysis will be incorporated into the final report to the Australian Government for their decision.

The policy assessment criteria for the impact analysis includes:

- Achieve appreciable health and environmental outcomes

- Ensure the most effective operation of non-road diesel engines

- Facilitate adoption of better non-road diesel engine and emission control technologies

- Reduction in greenhouse gas emissions

- Achieve harmonisation with international standards

- Maximise net national benefits

The draft analysis says that most developed nations have national noxious emissions standards for non-road diesel engines and that comparable nations implemented such standards more than 20 years ago.

According to the analysis in 2018, non-road diesel engines in Australia emitted 104 kilotonnes (kt) of CO, 19.5 kt of THC, 312 kt of NOX, 13.4 kt of PM10, 13.0 kt of PM2.5, 178 t of SO2 and 29.5 megatonnes (Mt) of CO2.

“Non-road diesel engines are likely to be responsible for around 10-15 per cent of national anthropogenic NOX emissions, up to 5 per cent of PM2.5 emissions, around 1-2 per cent of PM10 emissions and approximately 5 per cent of national GHG emissions,” states the analysis.

“These emissions resulted in a combined annual years of life lost (YLL) for the whole of Australia of 5,387, equating to a cost to society of $1.6 billion (real 2021 prices).

“This equated to around 9% of all YLL due to anthropogenic (all source) PM2.5 and NO2 concentrations in Australia. Health impacts and costs would continue to be incurred in future years.”

BHP already planning an end to diesel-powered trucks

While the federal government considers regulation, industry is moving ahead on decarbonisation because of cost savings.

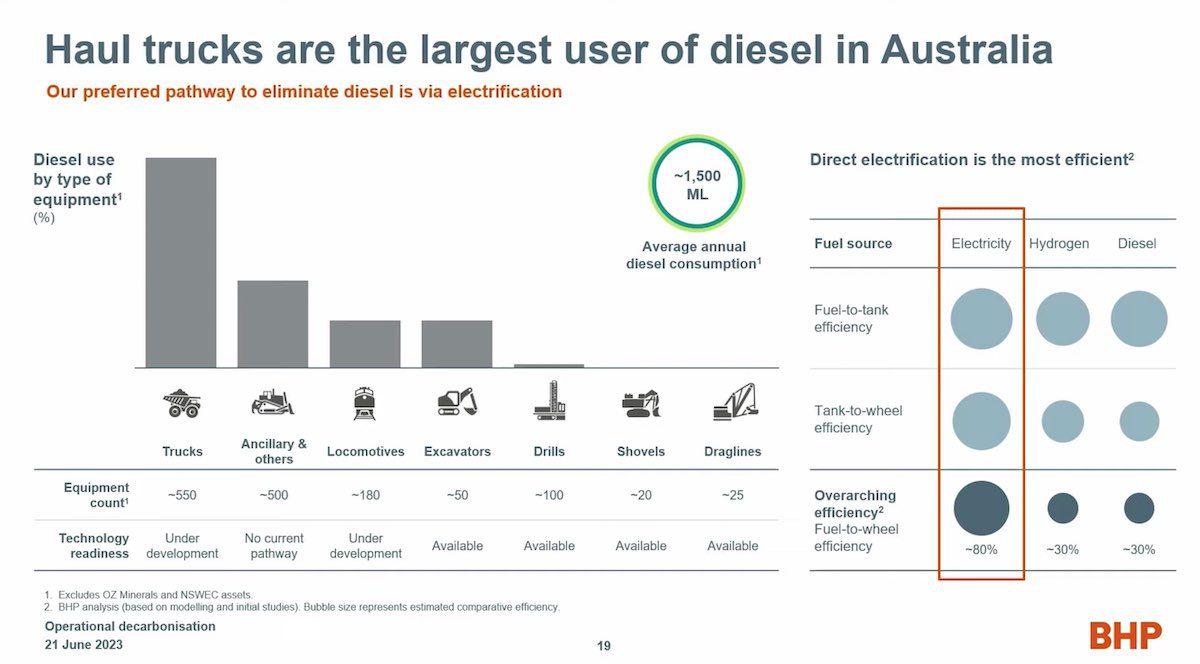

Two weeks ago BHP unveiled plans to replace its fleet of diesel trucks with electric trucks, in a staged transition that will not only reduce the company’s scope 1 emissions but also provide huge savings on operational costs. It followed similar assessments by mining rivals Rio Tinto and Fortescue Metals.

“Each year our Australian operations use roughly 1,500 mega litres of diesel in over 1,000 pieces of equipment,” said BHP vice president of planning and technical minerals Australia Anna Wiley.

“Over half of this is used in our truck fleets. Electrification is the preferred pathway to eliminate this diesel. Part of the reason for this is energy efficiency.”

Wiley went on to explain the huge differences in energy efficiency between diesel, hydrogen and electric trucks (shown in the table on the right in the image above).

“The first row represents the fuel movement from source to the equipment. Using hydrogen as an example, you can see that the greatest losses at this phase are due to generation storage and transmission compared to minimal losses in electricity generation and transmission.

“Once on board, the fuel needs to be transferred into energy. In both today’s diesel electric technology and in a hydrogen system, the fuel is used to generate electricity to drive the electric wheel motors which has additional losses.

“Putting this together in the bottom row, we can see that around 80% of overall efficiency from electrified pathway compared to less than half of this for hydrogen.”

But the fuel cost savings are even higher than BHP’s analysis suggests. Wiley’s comparison begins with the hydrogen fuel already created. There are also massive losses involved in creating hydrogen which brings overall hydrogen efficiency down to around 20%.

No safe level of exposure to diesel exhaust pollutants

While some in industry are finally planning a move away from diesel powered equipment, the government analysis says that non-road diesel equipment is actually set to increase in coming years. Strong government regulation is vital to accelerating non-road equipment to fully-fully electric.

The draft impact analysis notes that the 2021 State of the Environment Report states there may be no ‘safe’ level of exposure to some pollutants, in particular fine particulate matter (PM2.5) which is a key well-being indicator for the UN’s sustainable development goals.

“Peak reported levels of PM2.5 were above the national standards in all Australian cities, and levels are increasing in many locations. Exposure to PM2.5 is estimated to be responsible for around 2 per cent of all deaths in Australia (Emmerson & Keywood, 2021),” it says.

“Using technology already available in the market that meets non-road diesel engine emission standards can reduce the death rate.”

The analysis says there was around 640,000 non-road diesel engines in Australia in 2018 and that number is projected to increase to 750,000 by 2028 and around 945,000 by 2043.

The impact analysis also says that despite on-road diesel engines numbering around five million, almost 8 times the number of non-road diesel engines, Australian non-road diesel engines consume a comparable total volume of diesel.

This means non-road diesel engines represent a gaping hole in Australia’s pollution reduction policy.

The government is taking public submissions on the draft impact analysis until 5pm Friday, July 14.

Daniel Bleakley is a clean technology researcher and advocate with a background in engineering and business. He has a strong interest in electric vehicles, renewable energy, manufacturing and public policy.