Australian fast charger manufacturer Tritium has opened a new “world-class” EV charger testing facility at its Brisbane headquarters that will accelerate testing, prototyping, compliance, and certification of its equipment./

“As passenger and fleet EVs with larger battery packs come online, demand for higher-powered DC fast chargers is expected to increase,” said Jane Hunter, Tritium CEO.

“The more rapidly we can develop new products to meet the needs of this fast-evolving market and complete testing of those products for public use, the faster we can deliver chargers that meet that demand. This cutting-edge facility is expected to enable us to deliver world-leading charging infrastructure to our customers across the globe.”

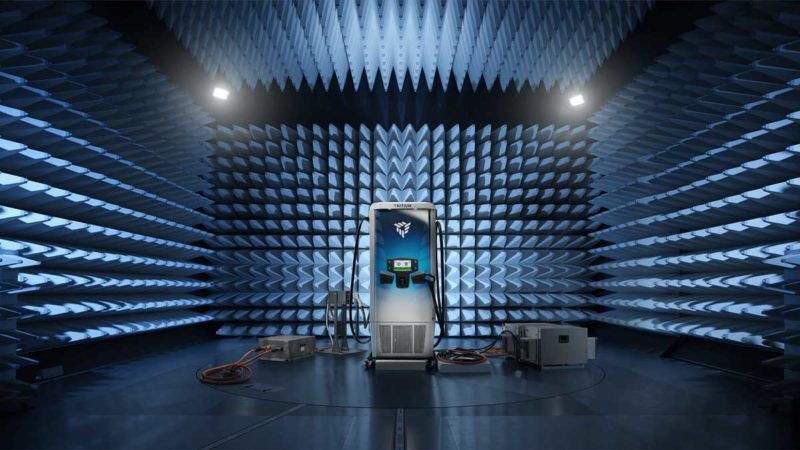

Tritium’s new testing facility includes an electromagnetic compatibility (EMC) testing chamber with one of the highest power test capabilities in the world, according to the company.

The new custom-designed EMC testing chamber features a five-metre turntable with high-power connections, meaning that Tritium is able to test a full high-powered charging system including both the charger itself and accompanying power cabinet.

Without being able to claim an EMC testing chamber for their own, many EV charger manufacturers around the globe must rely on publicly accessible EMC testing facilities with advance booking notice and for testing periods as short as 1 to 2 weeks.

If, however, re-testing is necessary, the whole process must be restarted, with manufacturers returning to the back of the queue for access. These delays are translated into longer delivery to market times.

“We now have the freedom to test a charger at a moment’s notice and for as long as we need, to ensure our chargers not only meet the thresholds required for compliance but exceed them,” said James Kennedy, Tritium CTO and co-founder.

“We believe that taking away the time constraints of a commercial facility, combined with the ability to test in one of the most powerful and advanced facilities of its kind, will enable us to rapidly create and certify market-ready products more cost-efficiently and to add features and customizations to more effectively meet the needs of our customers.”

In addition to its sought-after EMC testing chamber, Tritium’s new testing facility also plays host to two thermal chambers used to test equipment in extreme temperatures.

For example, the thermal chamber allows for charger testing in up to 98% humidity and in temperatures ranging from -40°C (-40°F) to +70°C (+158°F), while the thermal chamber for testing modules and components is capable of producing temperatures ranging from -70°C (-94°F) to +180°C (+356°F).

Those interested in learning more about Tritium’s new testing facilities can now take a virtual interactive tour on the company’s website.

News of the facility’s opening was similarly welcomed by the Brisbane government.

“Tritium is changing the face of the global electric vehicle (EV) industry, and we’re so proud to be here today to open a world-class compliance testing facility at the company’s Brisbane headquarters,” said Steven Miles, Queensland’s deputy premier and minister for state development.

Joshua S. Hill is a Melbourne-based journalist who has been writing about climate change, clean technology, and electric vehicles for over 15 years. He has been reporting on electric vehicles and clean technologies for Renew Economy and The Driven since 2012. His preferred mode of transport is his feet.