Tesla has sold Maxwell Technologies, an ultracapacitor and dry cell technology company it acquired in 2019. But it is keeping the dry cell technology it harvested from its acquisition and is still working on commercialising it, Elon Musk said on Thursday.

Why exactly Tesla bought Maxwell came to light when in early 2020 Musk hinted that Maxwell’s technology would be “key” to the Cybertruck. Along with comments about increasing battery energy density, it became clear that it was Maxwell’s dry cell technology it was interested in.

Now, Tesla has sold Maxwell technologies to UCAP Power, the latter company confirmed in a statement last Wednesday. It will combine the company’s ultracapacitor capabilities with its current portfolio of patents to improve its products for turbines, energy storage and automotive.

Notably, UCAP employs several former staff of both Tesla and Maxwell Technologies. UCAP CEO Gordon Schenk, GM and president Troy Brandon were both formerly employed by Tesla while global sales manager Andrew Garcia was a sales director for Maxwell Technologies according to their LinkedIn profiles.

But Tesla has kept the dry cell tech, Musk confirmed today. In a tweet about the purchase by a follower, Musk responded that “Dry electrode is a key piece (one of many pieces) of the puzzle for lowering cost of lithium batteries.”

It was one of the pieces to the battery puzzle presented at Battery Day in 2020.

Although the day was considered an anti-climax by some, a grand plan to continue to decarbonise transport by increasing energy density and spreading battery material demand across a variety of battery types, both low energy density such as cobalt-free lithium-iron-phosphate batteries, and high-energy density, such as cobalt-nickel batteries, underpinned the reason for Battery Day’s being.

Musk also pointed out that while Tesla used the dry cell technology developed by Maxwell, it has done a lot of grunt work in bringing the tech to a commercially viable product.

“That said, it has required an *immense* amount of engineering to take Maxwell’s proof-of-concept to high-quality, volume production & we’re still not quite done,” said Musk.

Dry electrode is a key piece (one of many pieces) of the puzzle for lowering cost of lithium batteries.

That said, it has required an *immense* amount of engineering to take Maxwell’s proof-of-concept to high-quality, volume production & we’re still not quite done.

— Elon Musk (@elonmusk) July 21, 2021

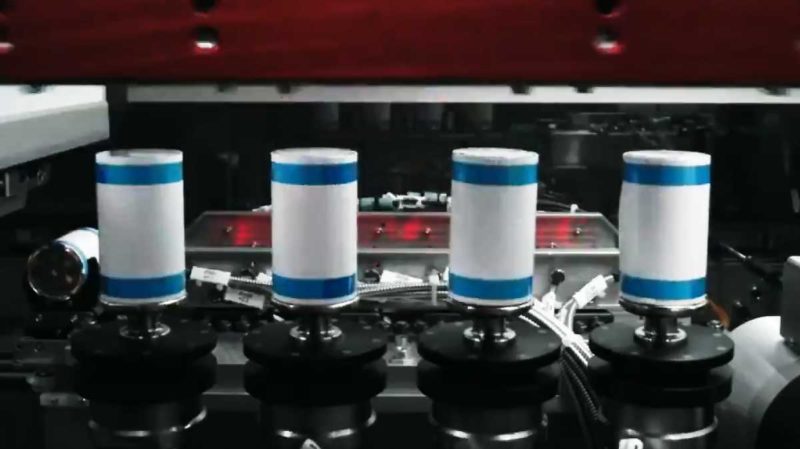

The commercially viable product in question is the 4680 battery presented at Battery Day, which not only helps to increase energy density by volume simply by having less gaps between each cell but also by introducing “tabless electrodes” as well as a range of other incremental improvements.

Key among these is using a dry electrolyte instead of the traditional wet format which reduces production costs, basically because it is less messy and takes up less room on the factory floor.

Bridie Schmidt is associate editor for The Driven, sister site of Renew Economy. She has been writing about electric vehicles since 2018, and has a keen interest in the role that zero-emissions transport has to play in sustainability. She has participated in podcasts such as Download This Show with Marc Fennell and Shirtloads of Science with Karl Kruszelnicki and is co-organiser of the Northern Rivers Electric Vehicle Forum. Bridie also owns a Tesla Model Y and has it available for hire on evee.com.au.